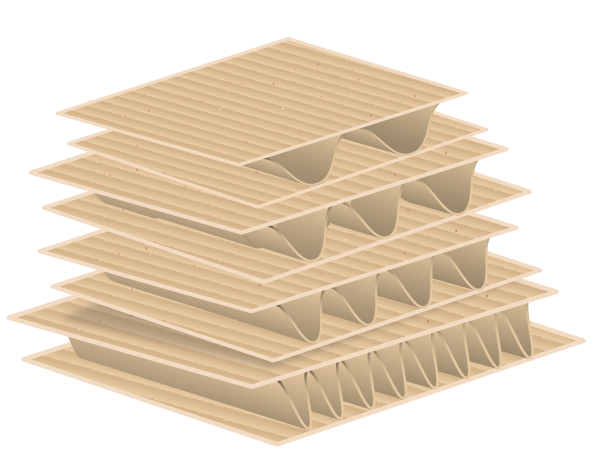

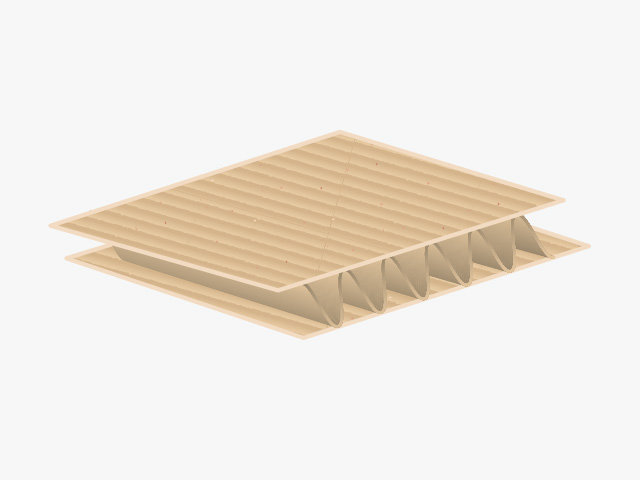

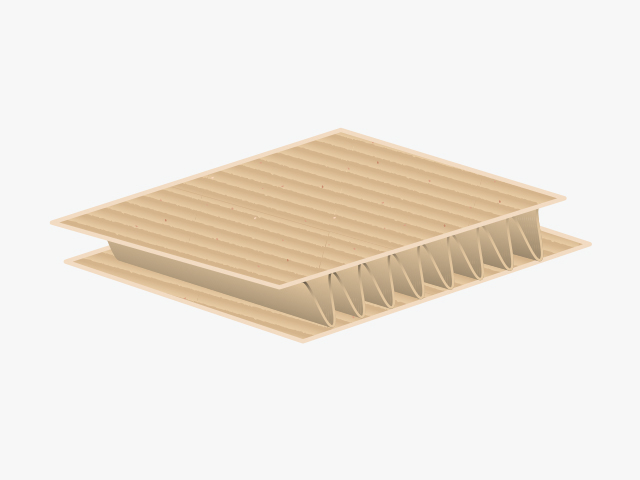

In the world of corrugated packaging, the “flute” refers to the wave or arch-shaped paper medium that forms the structure of the board’s corrugation. The type of flute used in the design significantly impacts the board’s strength, cushioning properties, and printability. Let’s dive into the different types of flutes commonly used in packaging.

Corrugated Cardboard Flutes

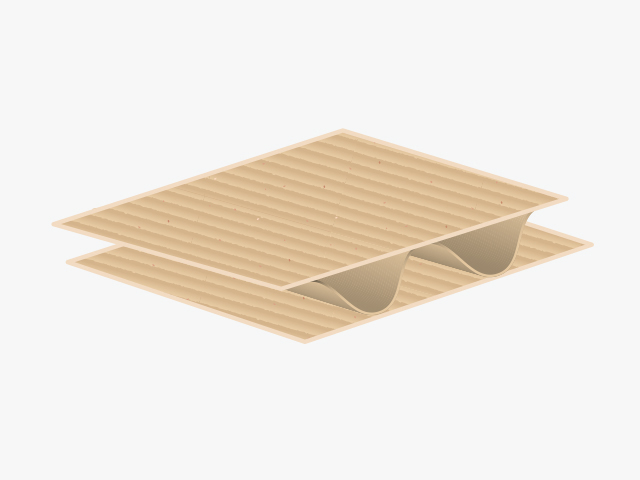

A-Flute: Maximum Cushioning and Stacking Strength

A-Flute is the thickest and provides the best cushioning and stacking qualities. It has excellent short column crush resistance, making it ideal for products that require robust protection during transportation. This flute type is typically used for packaging fragile items.

-

Flute Count: 32 to 37 flutes/foot

-

Thickness: Approximately 1/4″ (when combined with inner and outer liner)

-

Best for: High cushioning, stacking, and protection

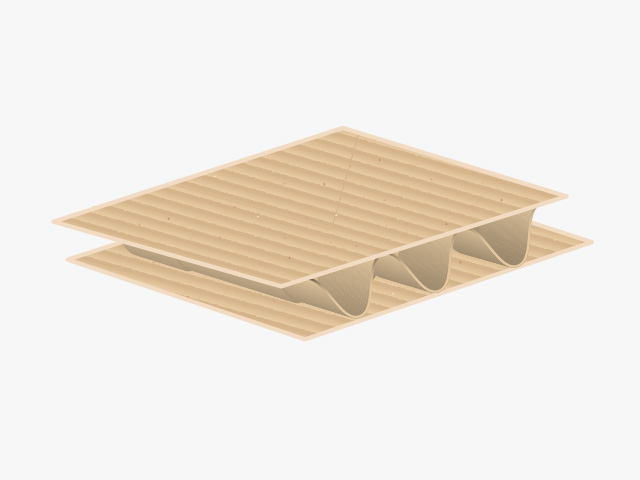

B-Flute: Balanced Strength and Flat Surface for Printing

B-Flute is thinner than A-Flute, with more flutes per foot, which provides a stiff, flat surface ideal for high-quality printing. The increased number of flutes offers excellent crush resistance, making it a great choice for retail packaging where both durability and presentation matter.

-

Flute Count: 45 to 52 flutes/foot

-

Thickness: Approximately 1/8″ (when combined with inner and outer liner)

-

Best for: High-quality printing and crush resistance

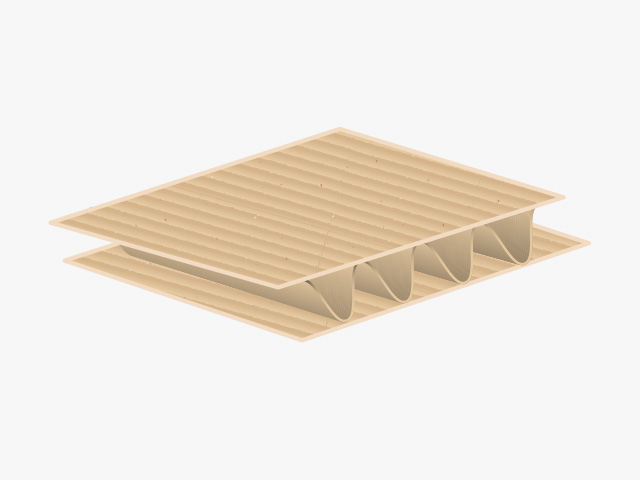

C-Flute: The Most Common Choice for Corrugated Packaging

C-Flute provides a balance between A and B flutes. It offers good cushioning, stacking, and printing properties, making it the most widely used flute size. It’s an excellent choice for general-purpose packaging needs, as it provides adequate protection while being cost-effective.

-

Flute Count: 39 to 43 flutes/foot

-

Thickness: Approximately 3/16″ (when combined with inner and outer liner)

-

Best for: Versatile use in general-purpose packaging

E-Flute: Thin, Flat, and Great for Printing

E-Flute is known for its fine surface and excellent crush resistance. Its thin profile (about one-quarter the thickness of A-Flute) reduces bulk and allows for better storage space optimization. It is highly suitable for high-quality printing applications, making it perfect for retail packaging with a premium look.

-

Flute Count: 92 to 98 flutes/foot

-

Thickness: Approximately 1/16″ (when combined with inner and outer liner)

-

Best for: Retail packaging and high-quality printing

F-Flute: The Latest Innovation in Packaging

F-Flute is the thinnest flute available, offering a rigid box structure with reduced fiber content. This flute was developed in Europe and has become the newest growth segment in the corrugated packaging industry. With 128 flutes per foot, F-Flute reduces the overall thickness of the packaging while maintaining rigidity and strength, making it ideal for lightweight, sturdy boxes.

-

Flute Count: 128 flutes/foot

-

Thickness: Approximately 1/32″ (when combined with inner and outer liner)

-

Best for: Lightweight, rigid packaging solutions

Contact Us

If You Have Any Questions Or Suggestions On How We Can Make Our Site More Useful, Please Contact Us.

Contact Info

Ontario Canada L3R 1G5

Areas We Serve

- Ajax

- Brampton

- Burlington

- Guelph

- Hamilton

- Kitchener

- Lincoln

- Markham

- Mississauga

- Oakville

- Oshawa

- Pickering

- Richmond Hill

- Toronto

- Vaughan